Suitable for single-pass spiral welding, oscillating welding, and strip electrode surfacing. Compatible with appropriate flux-cored welding wire for surfacing continuous casting machine rolls, blooming rolls, cold rolling mills, backup rolls, hot working rolls, etc. Particularly suitable as a replacement for HJ260 and HJ107 for surfacing small diameter rolls and shafts, solving the difficult problem of high-temperature slag removal. Under the same conditions, consumption is only 80% of that of fused flux.

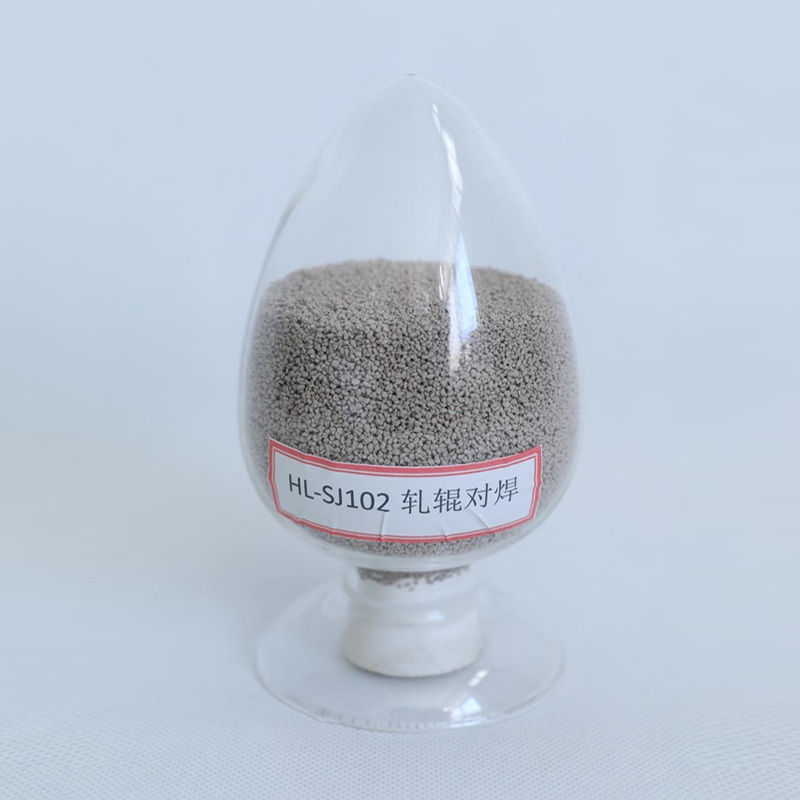

HL-SJ102 Hardfacing Welding Flux

HL-SJ102 flux is a fluorine-alkaline sintered flux with a basicity of approximately 2.0 and a bulk density of approximately 1.0. The flux has low S and P content and appears as light yellow spherical particles with a particle size range of 1.7-0.38mm (10-40 mesh). It is compatible with 1Cr13, 2Cr13, 3Cr13 and other welding wires or strips for surfacing continuous casting rolls, backup rolls, and various wear-resistant materials. When paired with appropriate alloy welding wire, it is suitable for surfacing various rolls and shafts with diameters ≥100mm.

This flux has "shorter" slag properties compared to HJ260, with lower chemical activity and good high-temperature (≥500℃) slag removal characteristics. It produces aesthetically pleasing weld beads with minimal alloy element burn-off, offering superior performance compared to HJ260 in all aspects. The surfacing layer hardness can reach 45-50HRC.